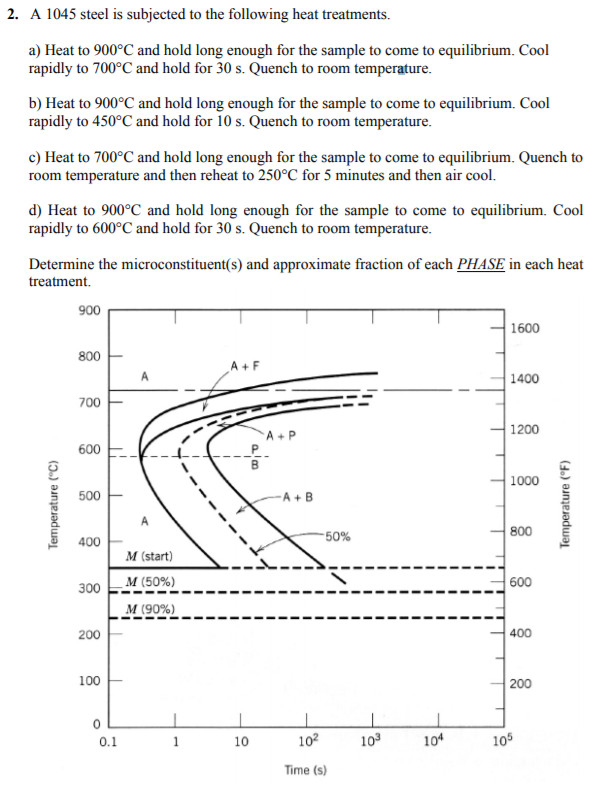

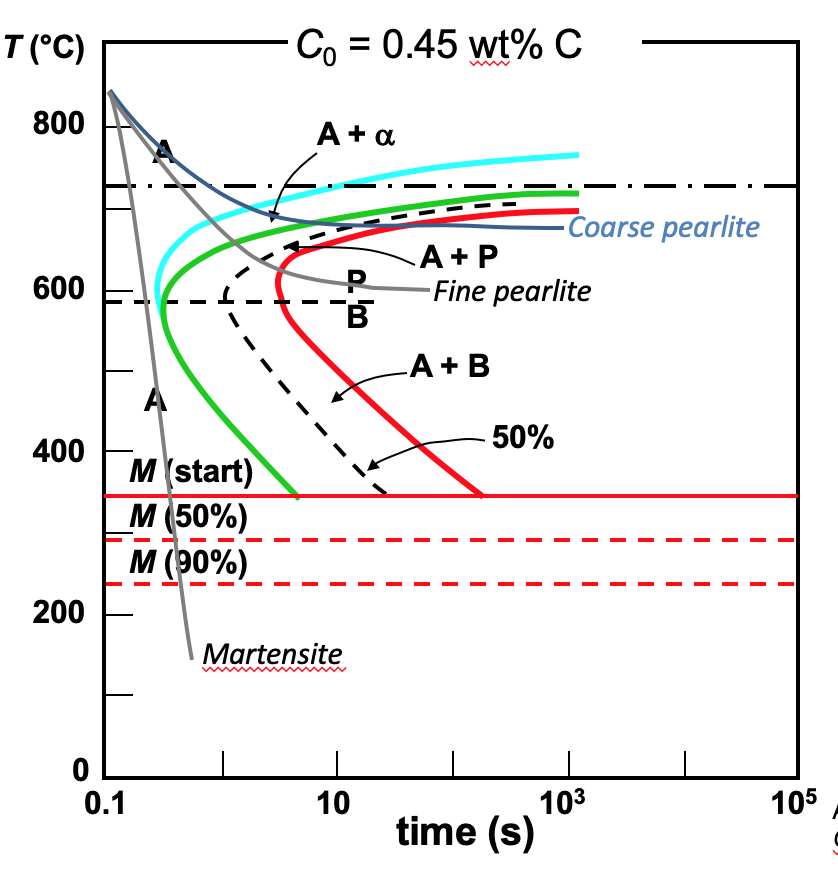

1045 Steel Heat Treatment

1045 steel heat treatment. Barbell bar material steel. Learn more about 4 types of heat treatment that steel can undergo. Can be carried DOI.

Based on the recommendations given by the machine manufacturers operations like tapping milling broaching drilling turning and sawing etc. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. Oil quench and draw from 400 deg for 57 rockwell to 1000 deg for 35 rockwell.

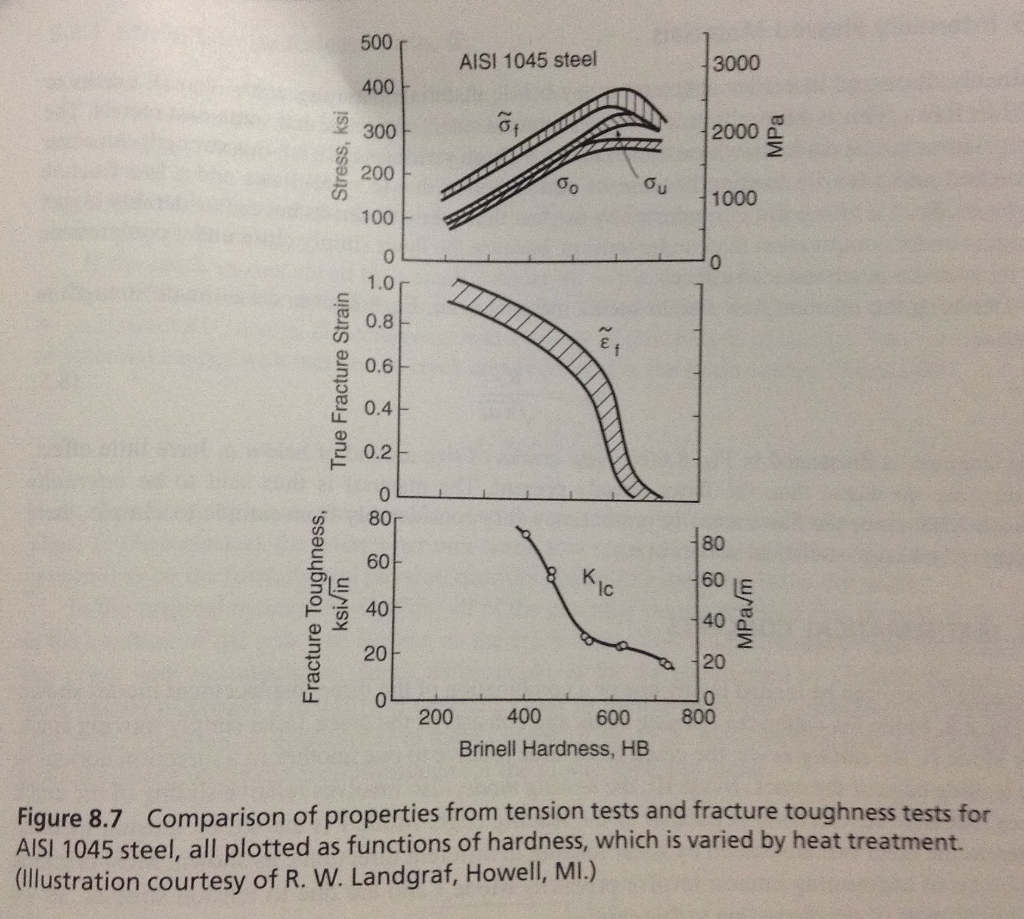

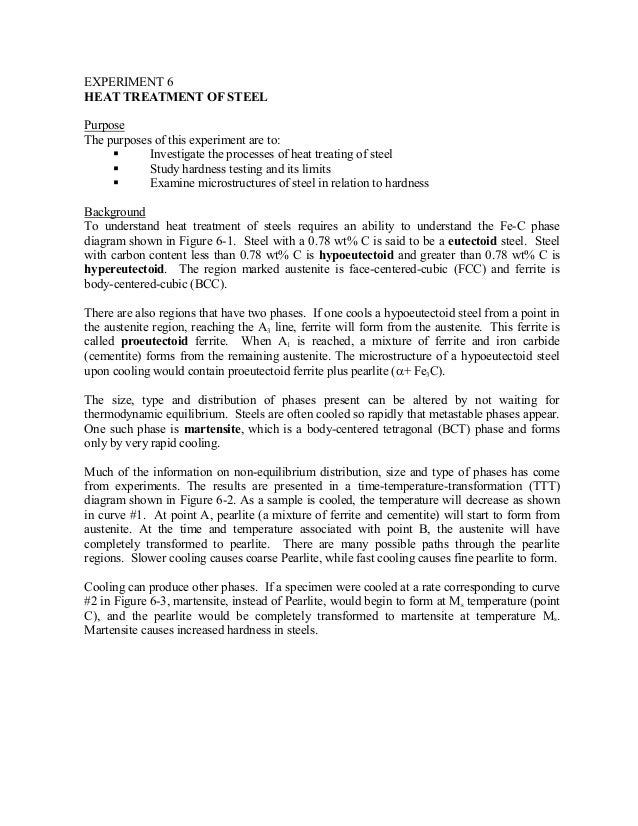

Tempering to temper 1045 first re-heat it to 400C 650C 752F 1202F as required and afterward hold it until the temperature is uniform. The experiment con- cluded that the quenchant affects the rate of cooling of the material which also affects the transformation of microstructure. In the present study AISI 1045 steel has been selected to analyze the effect of the heat treatment process on its hardness strength and toughness as this grade is used in numerous engineering applications nowadays.

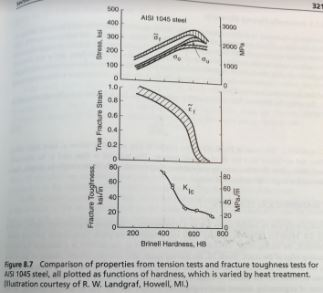

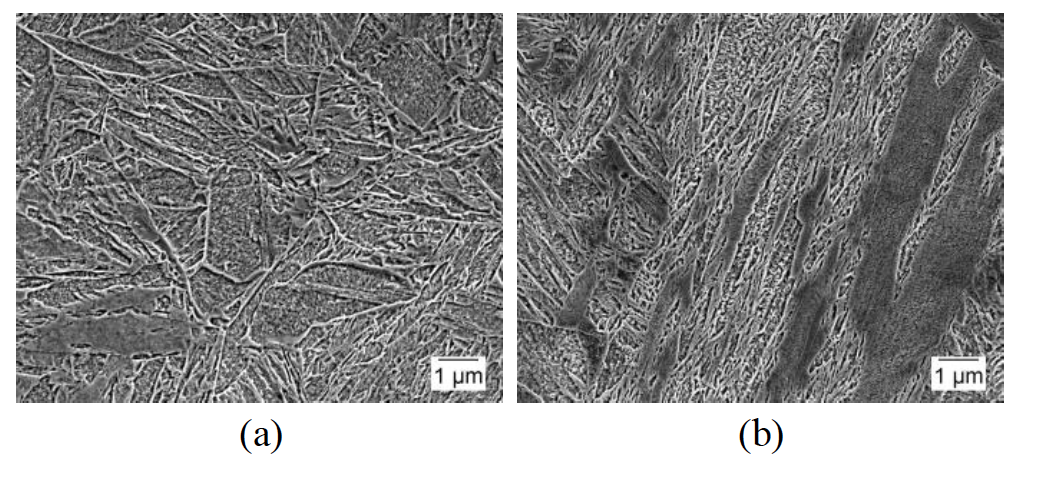

The effects of induction heat treatment on the formation of carbide particles and mechanical properties of spheroidized 1045 steel were investigated by means of microstructural analysis and tensile testing. The medium carbon steel of AISI 1045 steel has good machinability in normalized as well as the hot rolled condition. Heat treatment is an important mean to obtain excellent properties of all kinds of metal materials.

This is the typical heattreatment given to the steel by the manufacturer and is accordingly termed the asreceived condition. In order to determine if heat treatments can be discerned by nondestructive ultrasonic testing samples of SAE 1045 and SAE 4140 steels were subjected to the classical heat treatments of annealing normalizing quenching and quenching and tempering and their elastics constants Youngs shear and Poissons moduli were monitored by ultrasound. The AISI 1045 steel is treated by Annealing Furnace cooling Normalizing room temperature and Quenching water.

4135 steel chemical composition. Some common heattreatments for low and medium carbon steels. Not sure how hard you want it or the application of the finished product so the draw temp is your call.

S235jr s355jr cold drawn steel flat bar. Heat to 800C 850C 1472F 1562F Hold until the temperature is uniform Cool in furnace.

The induction spheroidization accelerated the formation of spherical cementite particles and effectively softened the steel.

The induction spheroidization accelerated the formation of spherical cementite particles and effectively softened the steel. Heat treatment is an important mean to obtain excellent properties of all kinds of metal materials. Can be carried DOI. The effects of induction heat treatment on the formation of carbide particles and mechanical properties of spheroidized 1045 steel were investigated by means of microstructural analysis and tensile testing. 4135 steel chemical composition. In the present study AISI 1045 steel has been selected to analyze the effect of the heat treatment process on its hardness strength and toughness as this grade is used in numerous engineering applications nowadays. 1045 Steel Heat Treatment - manufacturer factory supplier from China. For tempering 1045 steel was tempered at 300oC and 500 oC for 10 20 35 55 and 80 mins. 51200 Gcr15 Bearing Steel Round Bar.

The AISI 1045 steel is treated by Annealing Furnace cooling Normalizing room temperature and Quenching water. Harden at 1500 deg and soak 1 hr per in if thickness. 1045 Steel Round Bar Sheet Plate Heat Treatment Forging. Forging Annealing Normalizing Stress relieving Hardening Tempering Forging Heat to 850C - 1250C 1562F - 2282F Hold until the temperature is uniform Cool in furnace Annealing. Not sure how hard you want it or the application of the finished product so the draw temp is your call. Heat to 870C 920C 1598F-1688F. Hence modifying the hardness of the steel.

.jpg)

Post a Comment for "1045 Steel Heat Treatment"