Forklift Battery Watering System

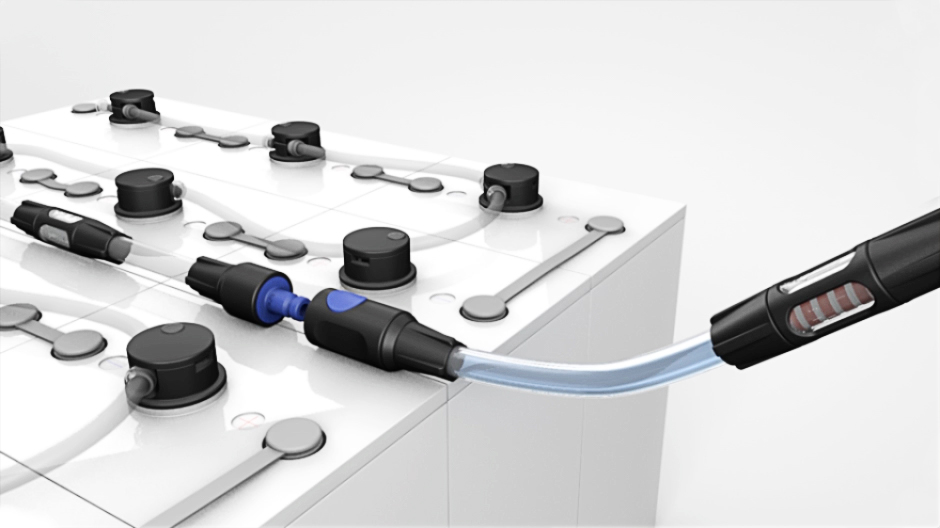

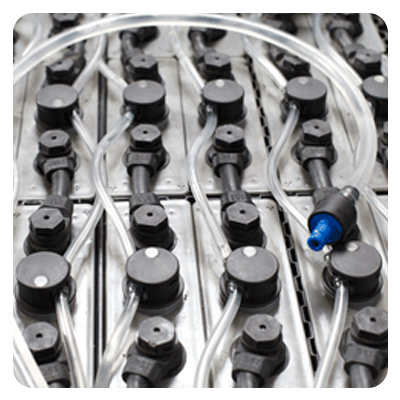

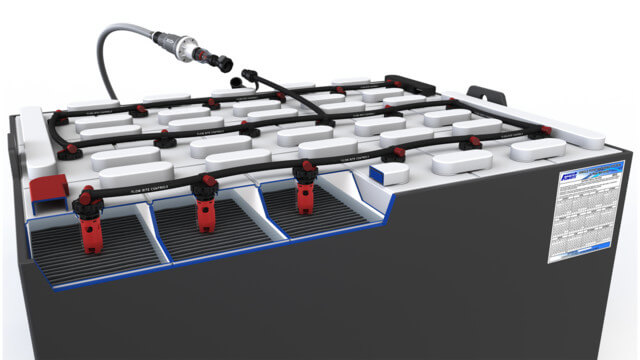

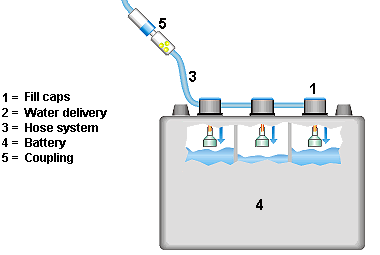

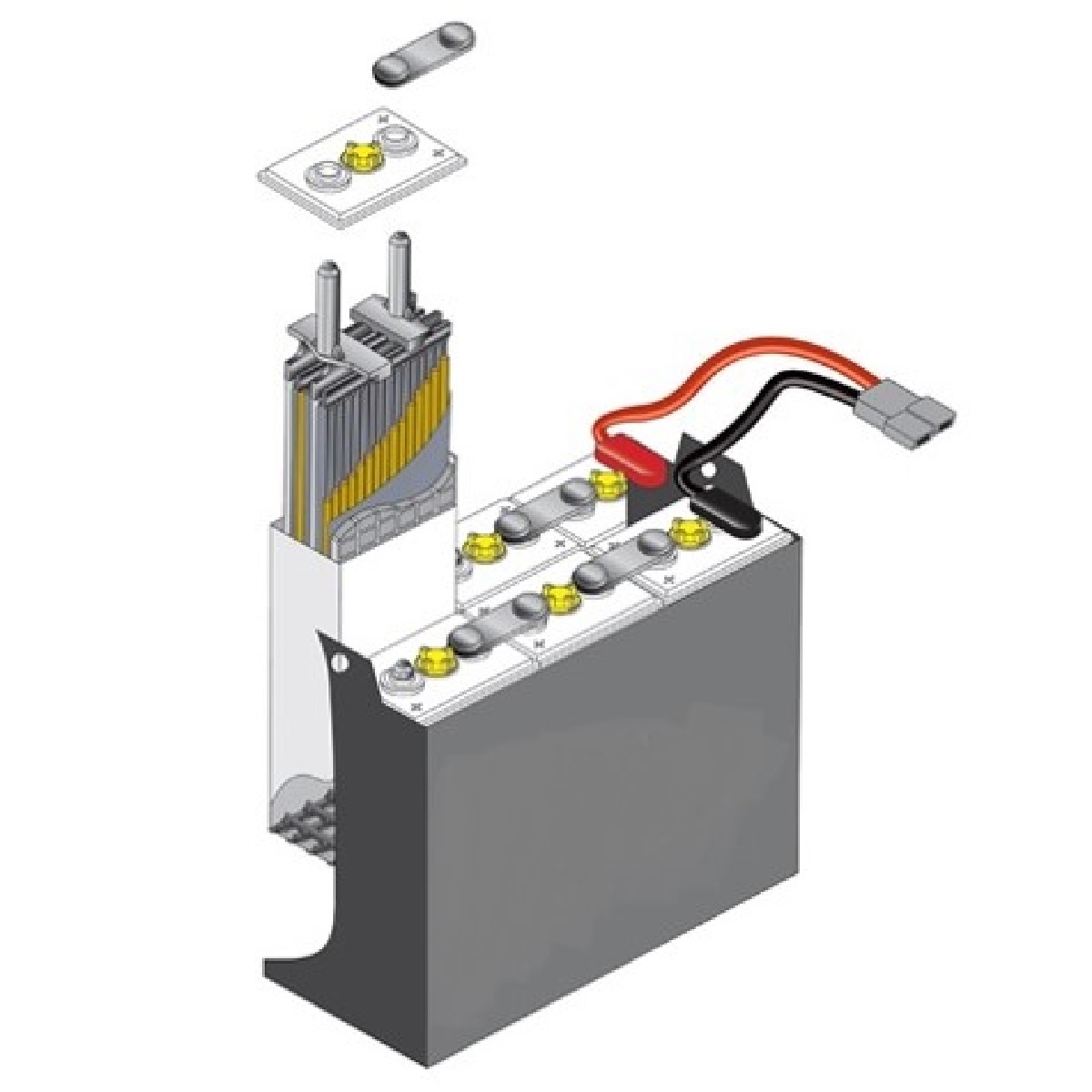

Forklift battery watering system. The same process happens when charging your forklift battery. A quick coupling allows the system to be connected to a water supply. Water injectors are installed into each cell on a battery and rugged tubing runs through each water injector forming a.

Once connected water flows into each cell until it reaches the correct level. They save time and labor making material handling operations like warehouses and distribution centers more efficient. Check out our watering system options below.

Facilities that use lead-acid batteries to power their forklifts must perform regular battery watering as a necessary part of regular maintenance and keeping electrolyte at optimal levels requires precision. Battery is watered perfectly This is eight times faster than filling a battery with a float-based system For most warehouses and distribution centers that adds up to hours of maintenance time saved each week Each Water Injector. Alpine Power Systems has vast range battery watering products for a variety of different motive power applications.

To make your new or existing forklift battery virtually maintenance free we recommend installing an automatic battery watering system and water level indicator light. And safer so operators dont need to remove batteries from their lift trucks to water their batteries. Method was very time consuming to water multiple batteries and also inaccurate with cells often being over or under filled leading to higher levels of battery damage.

A complete battery watering system will take all the work out of watering batteries. Its the latest in battery watering gun technology. Battery Watering Devices Systems.

Since every battery is different the Selectiva series automatically recognises age and charge level to provide a precise charge. This safe solution consists of automatic shut-off valves interconnected with tubing which replace battery vent caps. Once connected water flows into each cell until it reaches the correct level.

View Battery Water Deionizer Systems. Fronius Selectiva charging systems are highly intelligent.

Once connected water flows into each cell until it reaches the correct level.

The entire process takes just 30 seconds per battery. A flow indicator built into the water supply tells the operator when filling has been completed. Electricity and water dont mix until its time for forklift battery maintenance. This safe solution consists of automatic shut-off valves interconnected with tubing which replace battery vent caps. Once connected water flows into each cell until it reaches the correct level. The device will automatically shut off at exactly the right electrolyte level. Improper water levels can lower battery life and reduce cycle time between charges decreasing your forklifts effectiveness while. TypeForklift Battery Auto Watering System. Forklift battery maintenance its a chore but a necessity.

A quick coupling allows the system to be connected to a water supply. With Battery Watering Technologies single-point system theres no more opening vent caps manually and filling each cell individually. Lithium-ion batteries are sealed shut and the electricity-generating chemicals inside will stay inside requiring no liquid-related effort by forklift operators. Once connected water flows into each cell until it reaches the correct level. This safe solution consists of automatic shut-off valves interconnected with tubing which replace battery vent caps. GB will beat any advertised battery price. The GUN-X speeds up battery watering improves filling accuracy and importantly improves operator safety.

Post a Comment for "Forklift Battery Watering System"